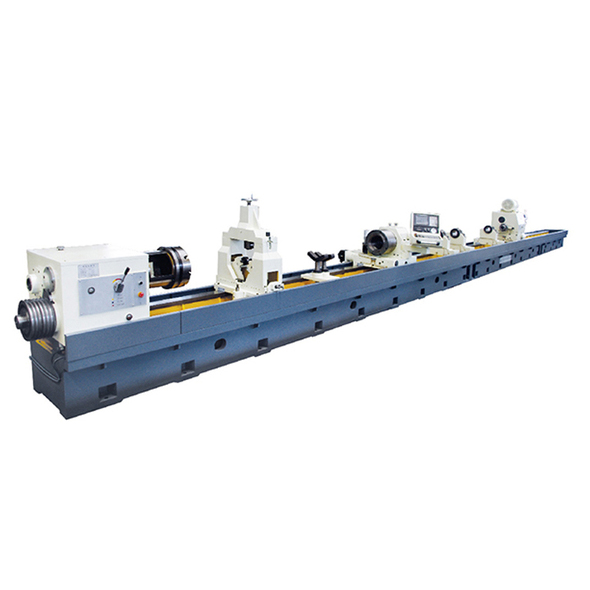

Imashini yo hejuru ya CNC Imashini yo gucukura

Twizera: Guhanga udushya nubugingo bwacu numwuka. Ubwiza ni ubuzima bwacu. Abaguzi bakeneye ni Imana yacu kumikorere yo hejuru ya CNC Glass Drilling Machine, Twumva ko inkunga yacu ishyushye kandi yinzobere izakuzanira ibintu bitunguranye ndetse n'amahirwe.

Twizera: Guhanga udushya nubugingo bwacu numwuka. Ubwiza ni ubuzima bwacu. Abaguzi bakeneye Imana yacuImashini yo gucukura ibirahuri byubushinwa hamwe nicyuma cyicyubahiro, Hamwe nuburambe bwimyaka irenga 9 hamwe nitsinda ryujuje ibyangombwa, twohereje ibicuruzwa byacu mubihugu byinshi no mukarere kwisi yose. Twishimiye abakiriya, amashyirahamwe yubucuruzi ninshuti ziturutse impande zose zisi kutwandikira no gushaka ubufatanye kubwinyungu rusange.

Umwirondoro wibikoresho

Iyi mashini niyambere yambere ya cooride eshatu CNC iremereye cyane yimashini icukura umwobo wimbitse mubushinwa, irangwa nubwonko burebure, ubujyakuzimu bunini nuburemere buremereye. Igenzurwa na sisitemu ya CNC kandi irashobora gukoreshwa mugutunganya ibihangano hamwe no gukwirakwiza umwobo; X. Imashini ikubiyemo gucukura umwobo wa BTA (gukuramo chip imbere) no gucukura imbunda (gukuramo chip yo hanze). Ibikorwa hamwe nogukwirakwiza umwobo birashobora gukorwa. Gukora neza neza hamwe nubuso bwubusanzwe busanzwe byemezwa no gucukura, gusubiramo no gusubiramo ibintu birashobora kugerwaho mubucukuzi bumwe.

Ibice nyamukuru bigize imikorere yimashini n'imiterere

1. Umubiri wo kuryama

X. Ibice bibiri byibitanda byateguwe muburyo bubangikanye, kandi buri gitanda cyuburiri gifite sisitemu ya servo ya sisitemu, ishobora gutahura kabiri-na-gukora-kabiri no kugenzura.

2. Agasanduku ko gucukura

Agasanduku k'imbunda ya drill agasanduku ni imiterere imwe ya spindle, itwarwa na moteri ya spindle, umukandara uhuza hamwe na pulley yoherejwe, kugenzura umuvuduko udasanzwe.

BTA drill rod box ni imiterere imwe ya spindle, itwarwa na moteri ya spindle, kugabanya binyuze mumukandara wa syncron na pulley yoherejwe, umuvuduko udashobora guhinduka.

3. Inkingi

Inkingi igizwe ninkingi nkuru ninkingi ifasha. Inkingi zombi zifite ibikoresho bya sisitemu ya servo, ishobora kumenya gutwara kabiri no kugenda kabiri, kugenzura.

4. Ikarita yo kuyobora imbunda, ibiryo bya BTA

Imfashanyigisho zimbunda zikoreshwa mu kuyobora imbunda zitwaje imbunda no gushyigikira inkoni.

Amavuta ya BTA akoreshwa mu kuyobora BTA imyitozo ya bito no gushyigikira inkoni ya BTA.

Ibipimo nyamukuru byimashini

Imbunda yo gucukura imbunda ya diameter --–5 ~φ35mm

BTA gucukura diameter intera --–25mm ~φ90mm

Gucukura imbunda Max. ubujyakuzimu —– 2500mm

BTA gucukura Max. ubujyakuzimu —— 5000mm

Z1 (imbunda y'imbunda) axis igaburira umuvuduko - 5 ~ 500mm / min

Umuvuduko wihuse wa Z1 (imyitozo yimbunda) axis -8000mm / min

Z (BTA) umurongo wo kugaburira umuvuduko –5 ~ 500mm / min

Umuvuduko wihuse wa Z (BTA) umurongo –8000mm / min

Umuvuduko wihuta wa X-axis --3000mm / min

Urugendo X-axis ——– 5500mm

X-axis ihagaze neza / gusubiramo umwanya - 0.08mm / 0.05mm

Umuvuduko wihuse wa Y-axis —–3000mm / min

Urugendo Y-axis - - 3000mm

Y-axis ihagaze neza / gusubiramo umwanya-0.08mm / 0.05mm

Twizera: Guhanga udushya nubugingo bwacu numwuka. Ubwiza ni ubuzima bwacu. Abaguzi bakeneye ni Imana yacu kubikorwa byo hejuru bya PLC Igenzura Ikirahure Cyimashini, Twumva ko inkunga yacu ishyushye kandi yinzobere izakuzanira ibintu bitangaje kimwe n'amahirwe.

Imashini ikora cyane Ubushinwa bwo gucukura ibirahuri hamwe n’imashini yo gucukura ibirahuri, Hamwe nuburambe bwimyaka irenga 9 hamwe nitsinda ryujuje ibyangombwa, twohereje ibicuruzwa byacu mubihugu byinshi no mukarere kwisi yose. Twishimiye abakiriya, amashyirahamwe yubucuruzi ninshuti ziturutse impande zose zisi kutwandikira no gushaka ubufatanye kubwinyungu rusange.