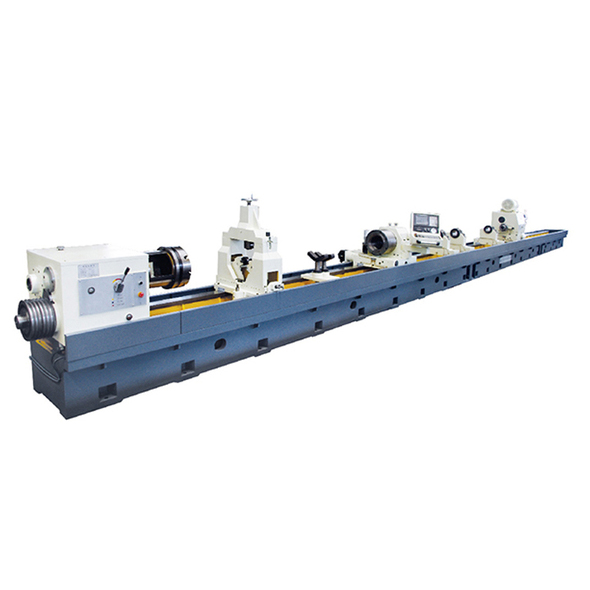

High Performance Ztk CNC Heavy Duty Deep-Hole Drilling and Boring Machine/Customerized Machine

We constantly believe that one’s character decides products’ high quality, the details decides products’ high-quality ,together with the REALISTIC,EFFICIENT AND INNOVATIVE crew spirit for High Performance Ztk CNC Heavy Duty Deep-Hole Drilling and Boring Machine/Customerized Machine, Our company quickly grew in size and name because of its absolute dedication to superior quality manufacturing, large value of goods and great customer provider.

We constantly believe that one’s character decides products’ high quality, the details decides products’ high-quality ,together with the REALISTIC,EFFICIENT AND INNOVATIVE crew spirit for China Heavy Duty Horizontal Lathe and CNC Machine, During in 11 years, We’ve participated in more than 20 exhibitions, obtains the highest praise from each customer. Our company has been devoting that “customer first” and committed to helping customers expand their business, so that they become the Big Boss !

Machine tool usage

● Such as machining spindle holes of machine tools, various mechanical hydraulic cylinders, cylindrical through holes, blind holes and stepped holes.

● The machine tool can not only undertake drilling, boring, but also rolling processing.

● Inner chip removal method is used when drilling.

● The machine bed has strong rigidity and good accuracy retention.

● The spindle speed range is wide. The feed system is driven by AC servo motor and adopts rack and pinion transmission, which can meet the needs of various deep hole processing techniques.

● The tightening of the oil applicator and the workpiece adopts the servo tightening device, which is controlled by CNC, which is safe and reliable.

● This machine tool is a series of products, and various deformed products can be provided according to customer needs.

Product Drawing

Product Drawing

The Main Technical Parameters

| The scope of work | |

| Drilling diameter range | Φ40~Φ80mm |

| Boring diameter range | Φ40~Φ200mm |

| Maximum boring depth | 1-16m (one size per meter) |

| Workpiece clamping diameter range | Φ50~Φ400mm |

| Spindle part | |

| Spindle center height | 400mm |

| Conical hole at the front end of the bedside box | Φ75 |

| Taper hole at the front end of the headstock spindle | Φ85 1:20 |

| Spindle speed range of headstock | 60~1000r/min; 12 grades |

| Feed part | |

| Feed speed range | 5-3200mm/min; stepless |

| Fast moving speed of pallet | 2m/min |

| Motor part | |

| Main motor power | 30kW |

| Feed motor power | 4.4kW |

| Oiler motor power | 4.4kW |

| Cooling pump motor power | 5.5kW x4 |

| Other parts | |

| Rail width | 600mm |

| Rated pressure of cooling system | 2.5MPa |

| Cooling system flow | 100, 200, 300, 400L/min |

| Rated working pressure of hydraulic system | 6.3MPa |

| The oil applicator can withstand the maximum axial force | 68kN |

| The maximum tightening force of the oil applicator to the workpiece | 20 kN |

| Drill pipe box part (optional) | |

| Taper hole at the front end of the drill rod box | Φ70 |

| Taper hole at the front end of the spindle of the drill rod box | Φ85 1:20 |

| Spindle speed range of drill rod box | 60~1200r/min; stepless |

| Drill pipe box motor power | 22KW variable frequency motor |

We constantly believe that one’s character decides products’ high quality, the details decides products’ high-quality ,together with the REALISTIC,EFFICIENT AND INNOVATIVE crew spirit for High Performance Ztk CNC Heavy Duty Deep-Hole Drilling and Boring Machine/Customerized Machine, Our company quickly grew in size and name because of its absolute dedication to superior quality manufacturing, large value of goods and great customer provider.

High Performance China Heavy Duty Horizontal Lathe and CNC Machine, During in 11 years, We’ve participated in more than 20 exhibitions, obtains the highest praise from each customer. Our company has been devoting that “customer first” and committed to helping customers expand their business, so that they become the Big Boss !