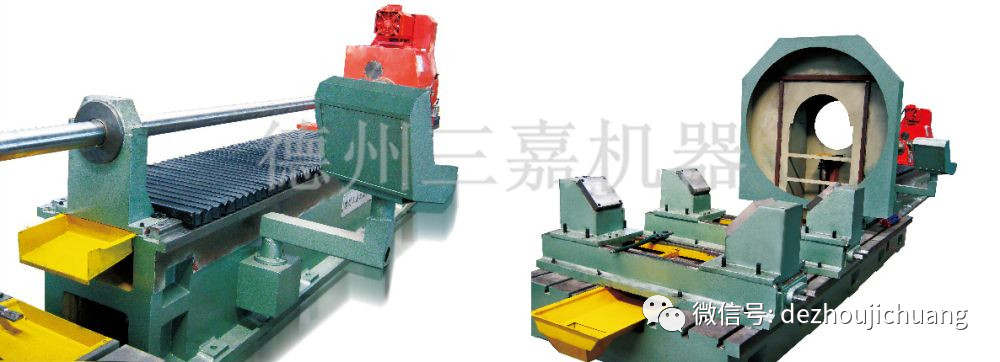

2MSK2150 CNC deep hole powerful honing machine is suitable for honing and polishing of cylindrical deep hole workpieces, such as various hydraulic cylinders, cylinders and other precision pipes. Honing and polishing of workpieces with stepped holes. The machining aperture accuracy can reach IT8-IT9 or above, and the surface roughness can reach Ra0.2-0.4μm. The use of local honing can correct the taper, ovality and local aperture error of the workpiece being processed. For some cold-drawn steel pipes, powerful honing can be performed directly. 2MSK2150 CNC deep hole powerful honing machine is an ideal equipment with high precision and high efficiency. The CNC deep hole powerful honing machine is equipped with KND CNC system, AC servo motor, and the grinding rod box adopts stepless speed regulation. The honing head is reciprocated by sprockets and chains, and the honing position can be accurately controlled. At the same time, double linear guides are used, which have a long service life and high precision. The honing head adopts hydraulic constant pressure expansion, and the honing force of the sand bar is stable to ensure the roundness and cylindricity of the workpiece. The honing pressure can be adjusted as needed, and high and low pressure controls can be set, and the rough and fine honing conversion can be easily achieved on the operating console. Other configurations of the machine tool are as follows: hydraulic valves, automatic lubrication stations, etc. use famous brand products. In addition, the CNC system, linear guides, hydraulic valves and other configurations of this CNC deep hole power honing machine can be selected or specified according to user requirements.

Main technical parameters

Working range

Processing diameter range———————————————Φ60~Φ500

Maximum processing depth———————————————1-12m

Workpiece clamping diameter range—————————————Φ150~Φ1400

Spindle part

Spindle center height (workpiece side)———————————1000mm

Spindle center height (grinding rod box side)—————————350mm

Grinding rod box part

Grinding rod box speed (stepless)———————————25~250r/min

Feed part

Drag plate reciprocating speed range—————————————4-18m/min

Motor part

Grinding rod box motor power—————————————15kW (frequency conversion)

Reciprocating motor power———————————————11kW

Other parts

Cooling system flow———————————————100L/min

Grinding head expansion working pressure—————————————4MPa

CNC

Beijing KND (standard) SIEMENS828 series, FANUC, etc. are optional, special machines can be made according to the workpiece conditions

Post time: Oct-03-2024