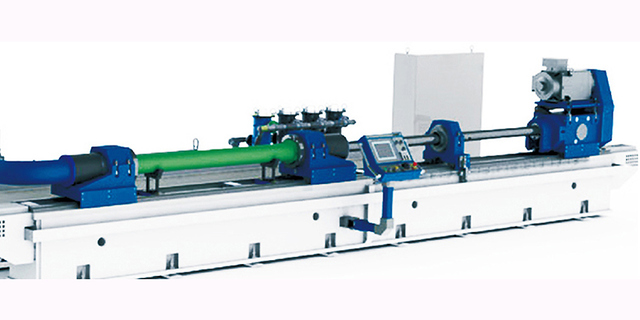

The CNC deep hole boring and scraping machine is 5-8 times more efficient than ordinary deep hole and honing. It is a processing equipment specialized in manufacturing hydraulic cylinders. It integrates rough boring and fine boring, uses push boring to complete rough and fine boring at one time, and uses the opportunity of tool withdrawal after boring to complete the rolling process at the same time. The rolling process makes the workpiece roughness reach Ra0.4.

Machining accuracy:

◆Workpiece boring surface roughness ≤Ra3.2μm

◆Workpiece rolling surface roughness ≤Ra0.4μm

◆Workpiece machining cylindricity ≤0.027/500mm

◆Workpiece machining roundness ≤0.02/100mm

Main technical parameters TGK35 TGK25

Working range

Boring diameter range————Φ40~Φ250mm——————Φ40~Φ350mm

Maximum boring depth————1-9m————————————1-9m

Workpiece clamping range——————Φ60~Φ300m————Φ60~Φ450mm

Spindle part

Spindle center height——————350mm——————————450mm

Boring bar box part

Spindle front end taper hole——————Φ100 1:20———————Φ100 1:20

Speed range (stepless)————30~1000r/min————30~1000r/min

Feeding part

Speed range (stepless)————5-1000mm/min————30~1000r/min

Panel rapid moving speed————3m/min—————————3m/min

Motor part

Boring box motor power————60kW———————————60kW

Hydraulic pump motor power—————1.5kW———————————1.5kW

Tightening frame rapid moving motor———4 kW————————————4 kW

Feeding motor power——————11kW———————————11kW

Cooling pump motor power—————7.5kWx2——————————7.5kWx3

Other parts

Cooling system rated pressure—————2.5 MPa——————————2.5 MPa

Cooling system flow rate————200, 400L/min————200, 400, 600L/min

Rated working pressure of hydraulic system————6.3MPa————————6.3MPa

Maximum tightening force of oiler————60kN————————————60kN

Magnetic separator flow rate————800L/min————————800L/min

Pressure bag filter flow rate————800L/min————————800L/min

Filter accuracy————50μm—————————————50μm

Post time: Oct-24-2024