TS2120 TS2135 TS2150 TS2250 TS2163 deep hole drilling and boring machine

Machine tool usage

● Inner chip removal method is used when drilling.

● The machine bed has strong rigidity and good accuracy retention.

● The spindle speed range is wide, and the feed system is driven by an AC servo motor, which can meet the needs of various deep hole processing techniques.

● Hydraulic device is adopted for the fastening of the oil applicator and the clamping of the workpiece, and the instrument display is safe and reliable.

● This machine tool is a series of products, and various deformed products can be provided according to customer needs.

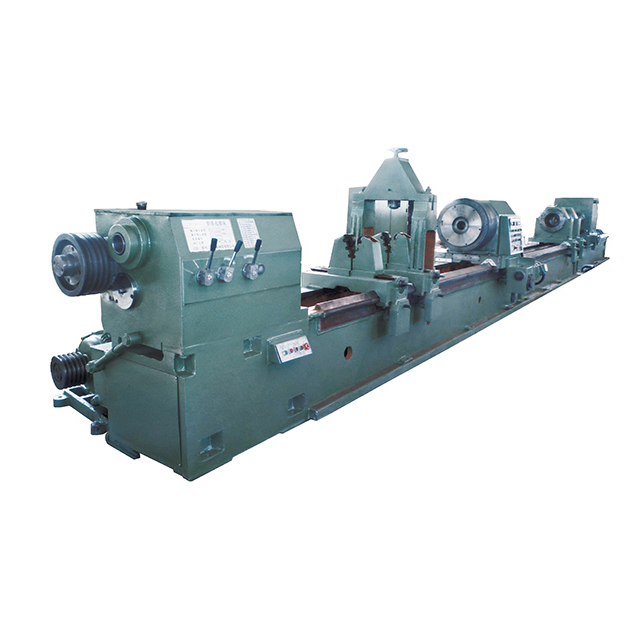

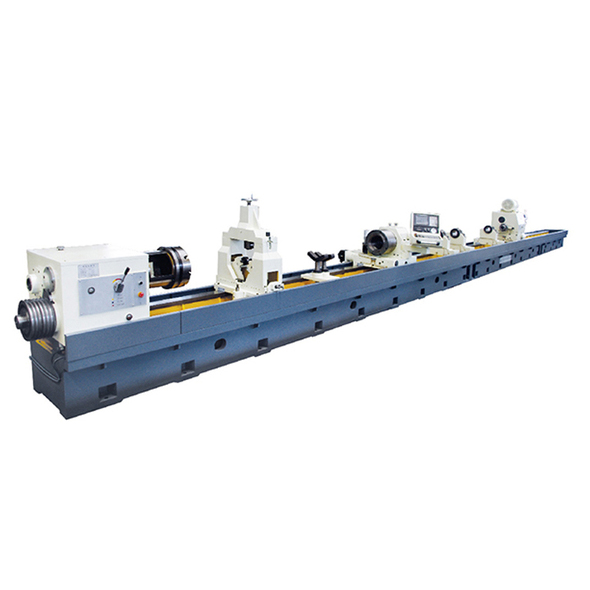

product drawing

The Main Technical Parameters

| The scope of work | TS2120/TS2135 | TS2150/TS2250 | TS2163 |

| Drilling diameter range | Φ40~Φ80mm | Φ40~Φ120mm | Φ40~Φ120mm |

| Maximum diameter of boring hole | Φ200mm/Φ350mm | Φ500mm | Φ630mm |

| Maximum boring depth | 1-16m (one size per meter) | 1-16m (one size per meter) | 1-16m (one size per meter) |

| Chuck clamping diameter range | Φ60~Φ300mm/Φ100~Φ400mm | Φ110~Φ670mm | Φ100~Φ800mm |

| Spindle part | |||

| Spindle center height | 350mm/450mm | 500/630mm | 630mm |

| Spindle aperture of headstock | Φ75mm—Φ130mm | Φ75 | Φ100mm |

| Taper hole at the front end of the headstock spindle | Φ85 1:20 | Φ140 1:20 | Φ120 1:20 |

| Spindle speed range of headstock | 42~670r/min; 12 levels | 3.15~315r/min; 21 level | 16~270r/min; 12 levels |

| Feed part | |||

| Feed speed range | 5-300mm/min; stepless | 5-400mm/min; stepless | 5-500mm/min; stepless |

| Fast moving speed of pallet | 2m/min | 2m/min | 2m/min |

| Motor part |

|||

| Main motor power | 30kW | 37kW | 45kW |

| Hydraulic pump motor power | 1.5kW | 1.5kW | 1.5kW |

| Fast moving motor power |

3 kW | 5.5 kW | 5.5 kW |

| Feed motor power | 4.7kW | 5.5 kW | 7.5 kW |

| Cooling pump motor power | 5.5kW×4 | 5.5kWx3+7.5kW (4 groups) | 5.5kWx3+7.5kW (4 groups) |

| Other parts | |||

| Rail width | 650mm | 800mm | 800mm |

| Rated pressure of cooling system | 2.5MPa | 2.5MPa | 2.5MPa |

| Cooling system flow | 100, 200, 300, 400L/min | 100, 200, 300, 600L/min | 100, 200, 300, 600L/min |

| Rated working pressure of hydraulic system | 6.3MPa | 6.3MPa | 6.3MPa |

| The oil applicator can withstand the maximum axial force | 68kN | 68kN | 68kN |

| The maximum tightening force of the oil applicator to the workpiece | 20 kN | 20 kN | 20 kN |

| Drill pipe box part (optional) | |||

| Taper hole at the front end of the drill pipe box | Φ100 | Φ100 | Φ100 |

| Taper hole at the front end of the spindle of the drill pipe box | Φ120 1;20 | Φ120 1;20 | Φ120 1;20 |

| Spindle speed range of the drill pipe box | 82~490r/min; level 6 | 82~490r/min; level 6 | 82~490r/min; 6 levels |

| Drill pipe box motor power | 30KW | 30KW | 30KW |

Write your message here and send it to us