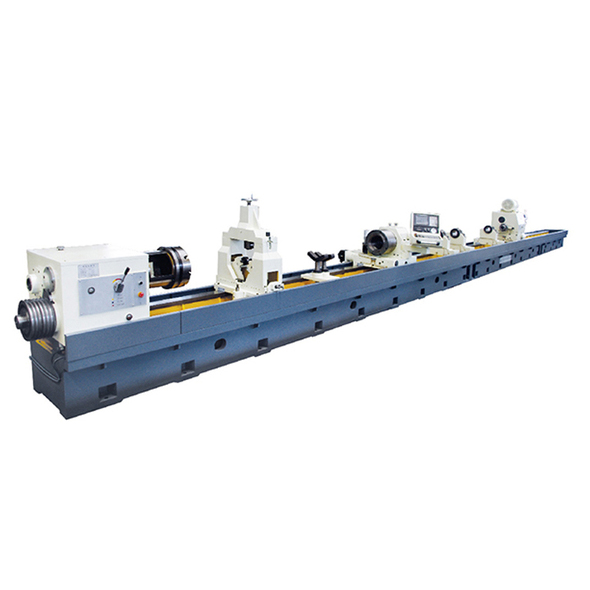

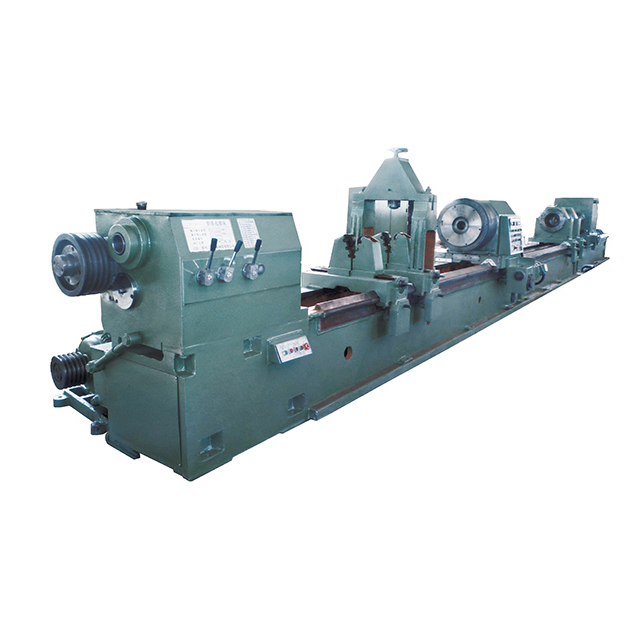

TS2180 TS2280 TSQ2180 TSQ2280deep hole drilling and boring machine

Machine tool usage

The bed guideway adopts double rectangular guideway which is suitable for deep hole machining machine, with large bearing capacity and good guiding accuracy; the guideway has been quenched and treated with high wear resistance. It is suitable for boring and rolling processing in machine tool manufacturing, locomotive, shipbuilding, coal machine, hydraulic, power machinery, wind machinery and other industries, so that the roughness of the workpiece reaches 0.4-0.8 μm. This series of deep hole boring machine can be selected according to the workpiece in the following working forms:

1. Workpiece rotating, tool rotating and reciprocating feeding movement.

2. Workpiece rotating, tool not rotating only reciprocating feeding movement.

3. Workpiece not rotating, tool rotating and reciprocating feeding movement.

4. Workpiece not rotating, tool rotating and reciprocating feeding movement.

5. Workpiece not rotating, tool rotating and reciprocating feeding movement.

6. Workpiece rotating, tool rotating and reciprocating feeding movement. rotation, tool rotation and reciprocating feeding movement.

The Main Technical Parameters

| The scope of work |

|

| Drilling diameter range | Φ40~Φ120mm |

| Maximum diameter of boring hole | Φ800mm |

| Nesting diameter range | Φ120~Φ320mm |

| Maximum boring depth | 1-16m (one size per meter) |

| Chuck clamping diameter range | Φ120~Φ1000mm |

| Spindle part | |

| Spindle center height | 800mm |

| Conical hole at the front end of the bedside box | Φ120 |

| Taper hole at the front end of the headstock spindle | Φ140 1:20 |

| Spindle speed range of the headstock | 16~270r/min; 21 levels |

| Feed part | |

| Feed speed range | 10-300mm/min; stepless |

| Fast moving speed of pallet | 2m/min |

| Motor part | |

| Main motor power | 45kW |

| Hydraulic pump motor power | 1.5kW |

| Fast moving motor power | 5.5 kW |

| Feed motor power | 7.5kW |

| Cooling pump motor power | 11kWx2+5.5kWx2 (4 groups) |

| Other parts | |

| Rail width | 1000mm |

| Rated pressure of cooling system | 2.5MPa |

| Cooling system flow | 200, 400, 600, 800L/min |

| Rated working pressure of hydraulic system | 6.3MPa |

| The oil applicator bears the maximum axial force | 68kN |

| The maximum tightening force of the oil applicator to the workpiece | 20 kN |

| Drill pipe box part (optional) | |

| Taper hole at the front end of the drill rod box | Φ100 |

| Taper hole at the front end of the spindle box spindle | Φ120 1:20 |

| Spindle speed range of the drill rod box | 82~490r/min; level 6 |

| Drill rod box motor power | 30KW |